Plastics 101

5.10.2023

5.10.2023

In the modern world, going an entire day without encountering plastic in some form or fashion is nearly impossible. From your toothbrush and shoes to your laptop and car, plastics are everywhere — but they are not all the same. Many of them have different properties, making them ideal for various uses.

In this blog, we will give you a rundown of the most common types of plastic out there, their properties, and where you’re likely to encounter them throughout your day. We’ll also look at some notable differences between virgin and recycled plastic and how Verdeco’s innovations in recycled plastics are paving the way for high-quality rPET.

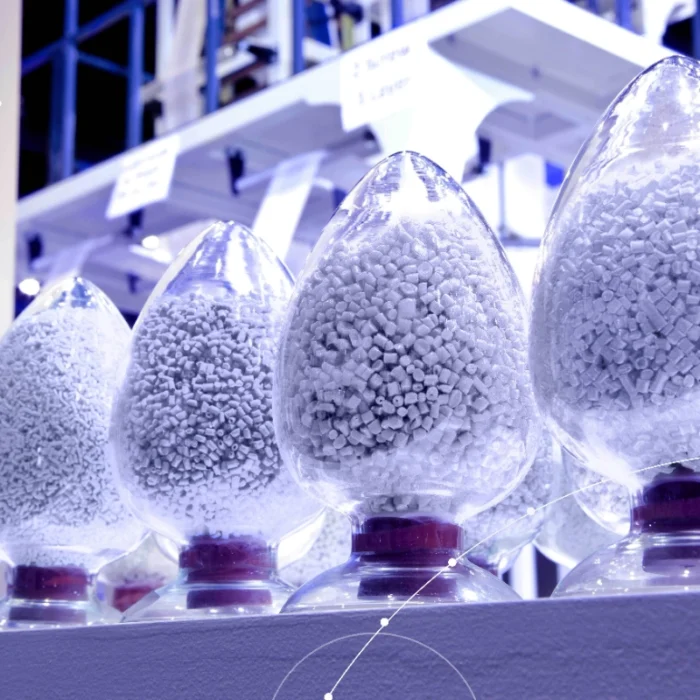

Short for polyethylene terephthalate, PET is one of the most common plastics in the world, and you likely interact with this kind of plastic on a daily basis. It is an ideal plastic for food and beverage containers because it is clear, lightweight, and provides an effective oxygen barrier that results in a longer shelf life for the products it packages. Additionally, PET is one of the most recyclable plastics.

Polyethylene is collectively the most popular plastic on the market, but it is classified into different types, which is how we get variations such as HDPE. High-density polyethylene is another plastic that is quite strong and resistant to moisture and chemicals. It is used to make milk cartons, detergent bottles, and publicly used commodities such as park benches.

Polyvinyl chloride, also known as vinyl, is a hard, rigid plastic that is resistant to chemicals and weathering. For this reason, it is widely used in building, construction, and medical applications. Some of the most common products made of PVC include plumbing pipes, credit cards, rain gutters, and medical fluid bags.

Low-density polyethylene (LDPE) is a softer, more flexible version of high-density polyethylene and is another standard household plastic. LDPE is often used to make cling wrap, bread bags, sandwich bags, and grocery bags.

As one of the most durable and heat-resistant plastics, polypropylene has a myriad of uses for products designed for repeated use. For example, bottle caps, CD cases, straws, and food storage containers are often made of polypropylene.

While you’re probably more familiar with its trademarked name, Styrofoam, polystyrene is a lightweight plastic widely used for its excellent insulating properties. Its various uses range from take-out containers and beverage cups to egg cartons and building insulation.

Of course, not all plastics fall under a single category. The ones that cannot be categorized end up as “other.” Plastics in this recycle code often combine multiple plastics that don’t align with one of the other six categories. Plastics with a recycling code 7 are rarely recyclable and include CDs, DVDs, car parts, eyewear, and greenhouses.

Recycled plastics require less energy and fewer natural resources to produce than their virgin plastic counterparts. Although they are more sustainable options that are better for the environment, some recycled plastics do not meet “virgin-quality” standards — that is, they may not perform as well as unrecycled plastics.

However, as recycling becomes a more sophisticated industry and feedstock becomes cleaner and better separated, many of these issues become less problematic. Additionally, many companies opt to use a blend of recycled and virgin plastics so that their packaging and products retain the quality they are looking for. Recycling technology is evolving daily, and over time, recycled plastics — like rPET — have become a viable alternative to virgin plastics.

rPET is nearly identical to PET and has the same qualities and properties. It is so similar that it falls under the same recycling code 1.

Many of the benefits of rPET relate to its environmental impact and sustainability. rPET is a sustainable alternative to PET, as it takes less energy to create and produces 79% fewer greenhouse emissions than virgin PET production. rPET has a carbon footprint of less than 25% of its unrecycled counterpart.It contributes to less waste in landfills, leaves less impact from extraction on the Earth, and can even help reduce CO2 emissions from transportation because of its lightweight properties.

Verdeco is making remarkable strides in developing customized rPET solutions with properties equal to virgin PET. We have developed an ultra-clear rPET with virtually no haze, even in packages that use 100% rPET. Additionally, our research and development teams are continually discovering new ways to make rPET the go-to material for companies that wish to create more sustainable packaging and products. We want our rPET to be top-of-mind, not just for the environmental benefits but also because of its inherent quality.

To learn more about Verdeco and how we’re changing the world, visit verdecorecycling.com.

Elevate your commitment to sustainability while upholding your high standards of quality. Talk with us today to discover the possibilities.